You’re spending too much on fog juice replacements because you haven’t optimized your storage protocols and machine efficiency settings. Most operators don’t realize that improper temperature control, incorrect fluid viscosity ratios, and inefficient timing sequences can reduce fog output by 40-60% per bottle. Your current approach likely wastes costly fluid through evaporation, contamination, and suboptimal atomization parameters, but specific adjustments to your storage environment and equipment calibration will dramatically extend your supply duration.

Proper Storage Techniques for Maximum Fog Juice Shelf Life

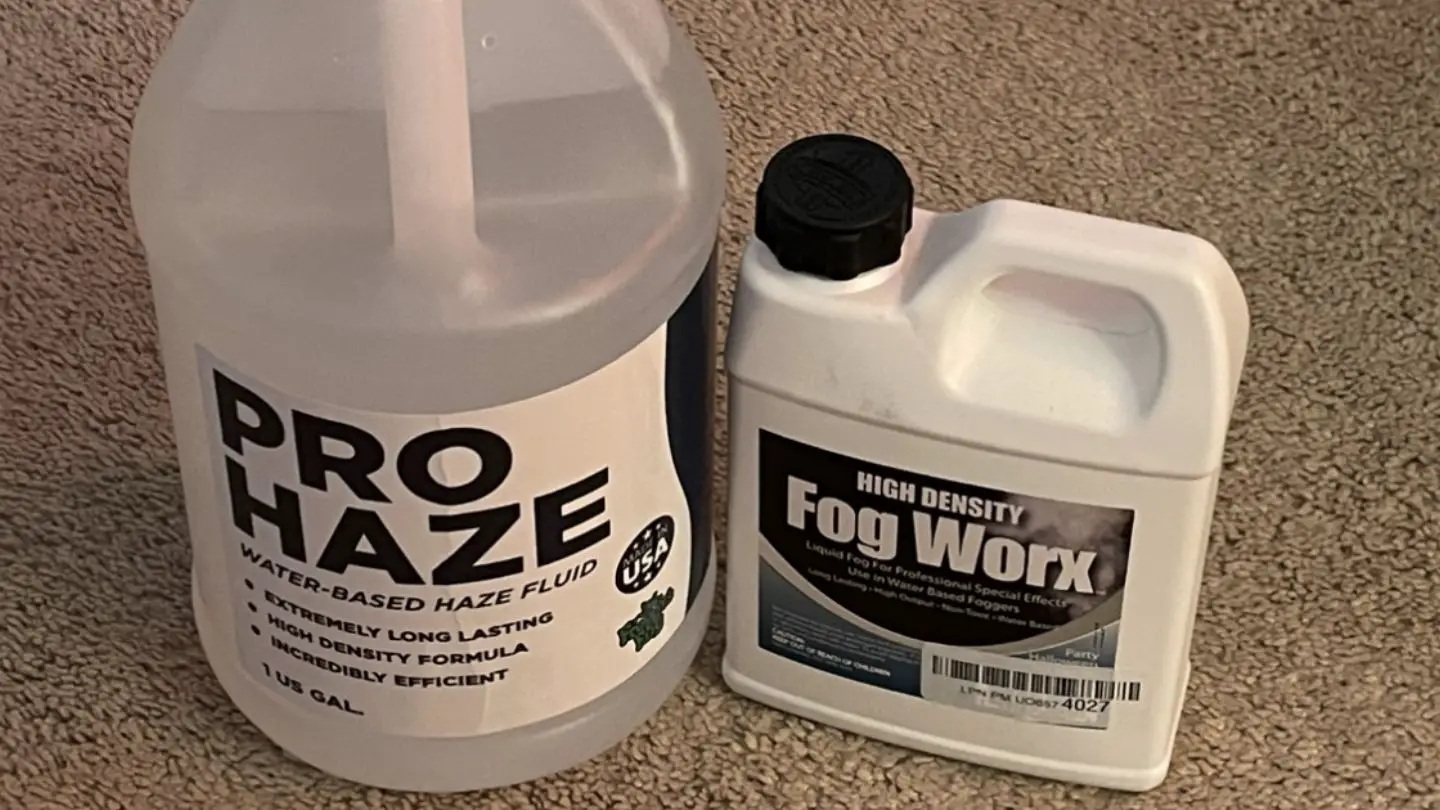

Proper storage greatly extends fog juice shelf life and maintains ideal performance in your fog machines.

Store containers in cool, dry environments between 50-70°F to prevent degradation. Keep fog juice away from direct sunlight and heat sources, which break down glycol compounds.

Seal containers tightly after each use to prevent contamination and evaporation. Don’t store opened bottles for more than two years, even under best conditions.

Check for sediment, cloudiness, or unusual odors before use—these indicate spoilage. Use original containers when possible, as they’re designed for proper chemical compatibility.

Label mixed solutions with preparation dates. Store away from children and pets in well-ventilated areas to maintain safety standards. Additionally, ensure that you do not dispose of fog fluid down the drain, as it can cause plumbing issues.

Optimal Machine Settings to Reduce Fog Juice Consumption

When you configure your fog machine’s output settings correctly, you’ll considerably reduce juice consumption while maintaining desired atmospheric effects.

Lower your heat setting to 70-80% capacity rather than maximum output. This reduces fluid vaporization rates while producing adequate fog density.

Adjust timer intervals to create intermittent bursts instead of continuous operation—15-second intervals with 30-second pauses work effectively for most applications.

Set your machine’s fan speed to medium rather than high to prevent rapid fluid depletion.

Monitor your fluid reservoir levels and avoid running the machine when fluid drops below minimum levels, as this damages heating elements and wastes remaining juice.

Use remote controls to precisely time fog output, eliminating unnecessary consumption during setup periods.

These adjustments can extend your fog juice usage by 40-60%. Additionally, always prioritize safety precautions to ensure optimal performance and prevent hazards during operation.

Strategic Timing Methods to Conserve Fog Fluid During Events

Strategic event timing requires careful coordination between your fog effects and performance schedules to maximize fluid efficiency.

You’ll achieve ideal conservation by synchronizing fog output with critical performance moments rather than maintaining continuous operation.

Implement these timing strategies:

- Pre-event warm-up cycles – Run 30-second fog bursts every 10 minutes to maintain machine readiness without waste.

- Cue-based activation – Trigger fog effects only during designated performance segments using DMX controllers or manual switches.

- Intermittent layering – Create atmospheric depth through 15-second intervals followed by 2-minute rest periods.

- Cool-down protocols – Reduce output intensity by 50% during venue shifts and equipment changes.

Additionally, understanding fog fluid consumption is essential for optimizing your fog machine’s performance and ensuring fluid lasts throughout the event.

Monitor your fluid levels continuously and adjust timing sequences based on remaining supply.

This systematic approach extends your fog juice life while maintaining professional-quality atmospheric effects throughout your event.

DIY Fog Juice Recipes That Deliver More Output Per Batch

Beyond optimizing your timing techniques, you’ll maximize fog machine efficiency by formulating your own high-output fog juice blends.

Start with distilled water as your base—tap water’s minerals will clog heating elements and reduce output density. Mix 15-20% glycerin with 80-85% distilled water for standard fog machines. For water-based units, substitute propylene glycol for glycerin at identical ratios.

Always use USP-grade chemicals to prevent equipment damage and guarantee safe operation. Higher glycol concentrations produce denser fog but consume more fluid per activation.

Test small batches first—incorrect ratios can overheat elements or create thin, dissipating vapor. Store homemade solutions in sealed containers away from direct sunlight. Label mixtures with concentration percentages and creation dates. Additionally, understanding the common liquid components used in fog machines can enhance your fog juice formulation.

This controlled approach typically yields 30-40% more visible fog output compared to commercial alternatives.

Maintenance Practices That Improve Fog Machine Efficiency

Regular cleaning and component inspection directly impact your fog machine’s fluid consumption and vapor output quality.

Proper maintenance prevents blockages that force your machine to work harder, consuming more juice while producing less fog.

Essential maintenance practices include:

- Clean heating elements monthly – Remove mineral deposits and residue buildup that reduce heat transfer efficiency.

- Inspect fluid lines quarterly – Check for clogs, kinks, or wear that restrict proper flow rates.

- Replace worn pump seals immediately – Damaged seals cause fluid leaks and pressure loss.

- Flush system with distilled water – Remove accumulated debris after every 40 hours of operation.

Neglecting these tasks leads to increased fluid waste, reduced fog density, and premature component failure. Additionally, cleaning fog machines regularly enhances their performance and efficiency.

You’ll extend both machine lifespan and juice efficiency by following manufacturer-recommended maintenance schedules consistently.

Frequently Asked Questions

Can I Mix Different Brands of Fog Juice Together Safely?

You can safely mix different fog juice brands if they’re both water-based or both oil-based formulations. Don’t mix water and oil-based fluids together, as this’ll damage your fog machine’s heating element and pump system.

How Do I Know When My Fog Juice Has Expired?

You’ll notice expired fog juice through visual inspection for cloudiness, precipitation, or color changes. Check for unusual odors, separation layers, or thickened consistency. Always verify expiration dates on containers and test small amounts before full machine operation.

What Should I Do if My Fog Juice Accidentally Freezes?

If your fog juice freezes, don’t panic. Thaw it completely at room temperature before use. Check for separation or crystallization. Gently mix if needed. Test viscosity and performance in your machine before operating.

Is It Safe to Use Fog Juice Around People With Asthma?

You shouldn’t use standard fog juice around people with asthma, as glycol-based fluids can trigger respiratory reactions. Consider water-based alternatives or consult medical professionals before operating fog machines in environments with asthmatic individuals present.

Can I Transport Fog Juice on an Airplane in Carry-On Luggage?

Like Icarus flying too close to regulations, you’ll face TSA restrictions. Fog juice exceeds 3.4-ounce liquid limits for carry-on bags. Pack it in checked luggage instead, ensuring secure container sealing prevents equipment contamination.

Conclusion

You’ll maximize fog juice longevity by implementing proper storage protocols and machine optimization. Consider Jake’s haunted attraction that extended juice life from six months to nearly two years by relocating storage from a heated warehouse to a climate-controlled room at 60°F. Don’t overlook temperature monitoring—even five-degree fluctuations accelerate glycol breakdown. Check your machine’s output settings regularly and maintain sealed containers between uses. These precision storage methods directly correlate with reduced replacement costs and consistent performance.